How DTF Transfers Are Made

Share

How DTF Transfers Are Made: A Comprehensive Guide by Dallas DTF Transfers

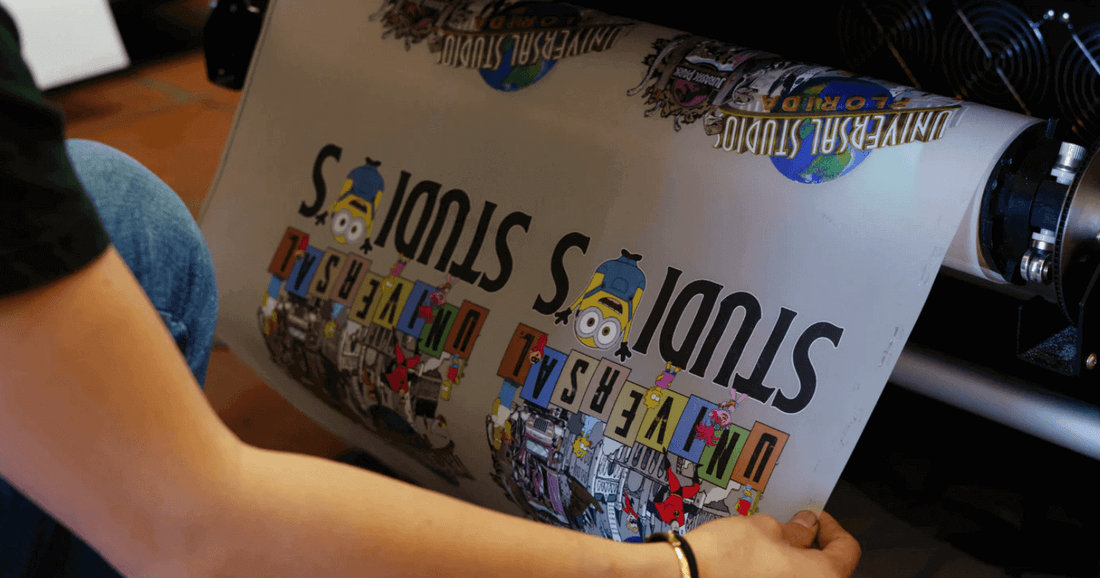

Direct-to-Film (DTF) transfers are a cutting-edge innovation in the custom printing industry, allowing for vibrant, durable designs to be applied to a wide range of materials. At Dallas DTF Transfers, we specialize in crafting high-quality DTF transfers that bring your creative visions to life. In this guide, we’ll walk you through the detailed process of how DTF transfers are made and what makes them an ideal solution for custom printing projects.

What Are DTF Transfers?

DTF transfers are pre-printed designs on specialized PET (polyethylene terephthalate) film that can be applied to fabrics and other surfaces using a heat press. These transfers eliminate many of the challenges associated with traditional printing methods, such as limited material compatibility and high setup costs, making them a preferred choice for businesses and individuals alike.

How DTF Transfers Are Made: Step by Step

The process of creating DTF transfers involves precision, specialized equipment, and high-quality materials. Here’s a step-by-step breakdown:

-

Design Creation Every DTF transfer begins with a digital design. High-resolution artwork is prepared using graphic design software to ensure crisp details and vibrant colors.

-

Printing on PET Film

-

The prepared design is printed onto PET film using a DTF printer.

-

The printer applies CMYK (cyan, magenta, yellow, and black) inks for full-color designs and white ink as a base layer, ensuring the design stands out on any fabric color.

-

-

Applying Adhesive Powder

-

A hot-melt adhesive powder is evenly sprinkled onto the printed film.

-

This powder bonds with the wet ink and will serve as the adhesive layer during the heat transfer process.

-

-

Curing the Film

-

The adhesive-coated film is cured using a curing unit or heat source.

-

This step ensures the powder adheres firmly to the ink, creating a ready-to-use transfer.

-

-

Heat Press Transfer

-

The PET film is placed onto the desired material, such as a T-shirt or hoodie.

-

A heat press applies high temperature and pressure, activating the adhesive and bonding the design to the fabric.

-

-

Peeling the Film

-

After the material has cooled, the PET film is peeled away, leaving behind a vibrant, durable design.

-

Why DTF Transfers Are Popular

DTF transfers are gaining traction in the custom printing industry for several reasons:

-

Versatility

-

They can be applied to a wide range of materials, including cotton, polyester, blends, and leather.

-

-

Durability

-

DTF transfers are resistant to cracking, peeling, and fading, even after multiple washes.

-

-

Vivid Colors

-

The printing process ensures vibrant, eye-catching designs with fine details.

-

-

No Fabric Pre-Treatment Required

-

Unlike some printing methods, DTF transfers do not require fabrics to be pre-treated, saving time and effort.

-

-

Eco-Friendly Options

-

Many DTF supplies, including inks and powders, are designed with sustainability in mind.

-

Applications of DTF Transfers

DTF transfers are ideal for a wide range of uses, including:

-

Custom Apparel: T-shirts, hoodies, and tote bags.

-

Sportswear: Jerseys and activewear.

-

Promotional Products: Branded items like hats and bags.

-

Personalized Gifts: Unique designs for special occasions.

-

Corporate Branding: Uniforms and branded merchandise.

DTF Transfers vs. Traditional Printing Methods

Here’s how DTF transfers compare to other popular printing methods:

| Feature | DTF Transfers | Screen Printing | Sublimation | DTG Printing |

|---|---|---|---|---|

| Fabric Compatibility | Cotton, Polyester, Blends | Limited to certain fabrics | Polyester only | Mostly cotton |

| Design Complexity | High | Medium | Medium | High |

| Cost for Small Runs | Low | High | Medium | High |

| Durability | Excellent | Excellent | Good | Good |

| Setup Time | Short | Long | Short | Medium |

Why Choose Dallas DTF Transfers?

At Dallas DTF Transfers, we’re committed to delivering the highest-quality DTF transfers that meet and exceed your expectations. Here’s why we’re a trusted name in the industry:

-

Premium Materials

-

We use the best PET films, inks, and powders for flawless results.

-

-

Fast Turnaround

-

Whether it’s a small or bulk order, we ensure quick delivery without compromising on quality.

-

-

Expert Guidance

-

From design assistance to final delivery, our team supports you at every step.

-

-

Custom Solutions

-

We cater to businesses and individuals, offering tailored services to suit your needs.

-

-

Eco-Friendly Practices

-

We prioritize sustainable solutions by using eco-friendly DTF supplies.

-

Getting Started with DTF Transfers

Ready to create stunning custom designs with DTF transfers? Here’s how to get started:

-

Contact Us

-

Reach out to our team at Dallas DTF Transfers to discuss your project requirements.

-

-

Upload Your Design

-

Share your artwork, and we’ll optimize it for the best printing results.

-

-

Place Your Order

-

Select from a variety of options, including gang sheets, single transfers, or custom apparel.

-

-

Enjoy Your Custom Prints

-

Sit back and let us handle the rest. Your high-quality DTF transfers will be ready in no time.

-

The Future of DTF Transfers

As technology advances, DTF transfers continue to evolve, offering even greater possibilities for customization, efficiency, and sustainability. At Dallas DTF Transfers, we stay ahead of the curve to provide our customers with the latest and best solutions for their printing needs.

Conclusion

DTF transfers are revolutionizing the custom printing industry, offering a versatile, durable, and cost-effective solution for businesses and individuals alike. Whether you’re looking to create custom apparel, promotional products, or unique gifts, Dallas DTF Transfers is your go-to partner for high-quality DTF transfer services. Contact us today to learn more about how we can bring your designs to life!